H2 from Biomass / Green Hydrogen

![]()

RAW MATERIAL

Wood residues from forestry, green waste, old wood, etc. No materials for industrial

use, no tank-plate discussion

![]()

PROCESS

The dried biomass of different types is converted into gas (synthesis gas) at 1200 degrees Celsius.

![]()

END PRODUCT

The synthesis gas produced from the biomass is broken down into its components: Hydrogen (H2) is produced in the highest degree of purity.

![]()

ECO-CYCLE

By-products such as CO and methane are used to generate and superheat steam and for biomass drying

![]()

GREEN H2

In contrast to the electrolysis process, gasification is completely CO2-neutral because only recycled biomass is used, or naturally renewable raw materials are applied.

|

|

RAW MATERIAL

|

|

|

PROCESS

|

|

|

END PRODUCT

|

|

|

ECO-CYCLE

|

|

|

GREEN H2

|

Technology

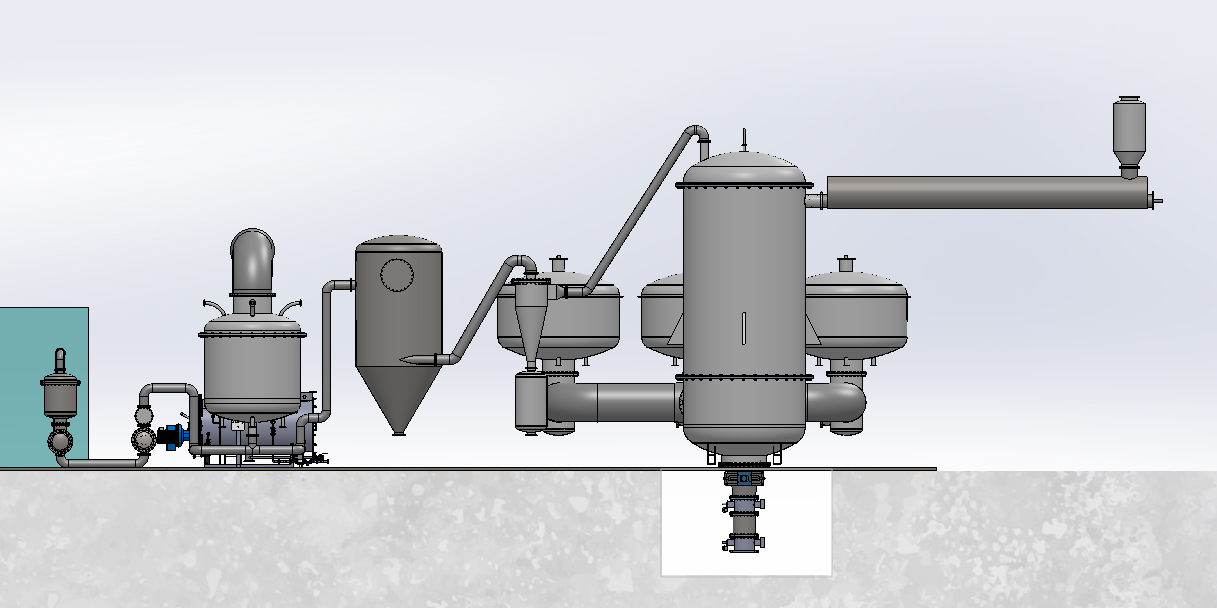

The HiTES technology for hydrogen production is based on allothermal steam reformation using energy from biomass. After the separation of hydrogen (H2) from the resulting gas mixture (synthesis gas), the remaining chemical and sensible energy is used to generate and superheat water vapor. It is also used to dry the biomass. This energy recycling results in a very high level of efficiency in the overall process.

This process was fully tested and operated with a pilot plant between 2007 and 2013. At that time, it was built, developed, researched and operated to produce synthetic fuel (so-called second-generation BtL) using Fischer-Tropsch synthesis.

Compared to the steam reformation of hydrogen from methane/natural gas, the net CO2 emissions from steam reformation from biomass are at least 13 times lower. Since the CO2 emissions from biomass can be considered neutral (circular CO2), only the emissions for the generation of the electricity used (depending on the current electricity mix) and for the transport of biomass are to be considered as climate-relevant CO2 emissions. Since the required electricity can be generated from renewable sources (such as electrolysis plants) and hydrogen-powered trucks will be used for transport in the future, the climate-damaging CO2 emissions are ultimately reduced to almost ZERO.

*Source BLUE HYDROGEN - SOLUTION OR PROBLEM OF THE ENERGY TRANSITION? FACTS, BACKGROUND, ARGUMENTS, GreenPeace Energy 2020

Compared to the production of hydrogen from electrolysis, the only similarity is that water is used as the source of the H2 molecules.

Instead of the large amount of electrical energy/electricity, the energy in a HiTES plant is obtained from biomass.

Electrical energy is only required as auxiliary energy for electrically operated plant components such as biomass extraction, gas compressors, pumps, etc. This makes it possible to produce GREEN hydrogen with electricity consumption reduced by at least a factor of 10.

This is particularly advantageous in regions with a poorly developed electricity grid and high biomass reserves, as well as in countries and regions with a low proportion of renewable electricity. Here, green hydrogen can be produced in large quantities using this technology under economically attractive conditions and a good contribution can be made to reducing CO2 in transport and industrial processes.

**"Screening Hydrogen Technology Handbook"; Th. Plankenbühler, S. Kolb, K. Herkendell, J. Karl, FAU Nuremberg 2021

The reactor used enables the use of various types of biomass, especially residual materials such as top wood (fresh from the forest), green waste, fermentation residues, old wood, agricultural waste, straw, nuts, etc. High-quality wood chips, materials for industry of biogenic origin or high-quality basic food products from agriculture are not required (no tank-plate discussion)!

Due to the low power consumption, the types of biomass / residual materials used and the relatively reasonable investment costs, the expected production costs (€/kgH2) are significantly lower than with other plants for the production of GREEN hydrogen!

Current projects

The planning and design of the industrial demonstration plant has been completed. Approval and execution are currently being prepared. Commissioning is planned for spring 2027.

| Production capacity of the demonstration plant: |

| Biomass input (atro): | 4 t/h | 24.000 t/a |

| H2 production | 400 kg/h | 2.400 t/a |

| Operating hours | 6.000 hours/year | |

| Time schedule: | ||

| Planning, ordering | 12 months | |

| Construction time | 12 months | |

| First commissioning with optimization | 12 months | |

SYSTEM DIAGRAM OF THE TECHNICAL PRE-PLANNING/DESIGN

TECHNICAL PLANT PRE-PLANNING/DESIGN AS A DIGITAL TWIN

After the demonstration plant has been commissioned, it is planned to plan and build further so-called standard plants in modular design. These standard plants will generally have twice the capacity. Lower investment costs are expected than for the so-called demonstration plant.

| Production capacity of the standard plant: |

| Biomass input (atro): | 4 t/h | 24.000 t/a |

| H2 production | 400 kg/h | 2.400 t/a |

| Operating hours | at least 6,000 hours/year | |

Publications

Patents

"Method and device for producing hydrogen" (3 patents at the DPMA)

"Method and device for converting chemical energy of a fuel into heat and electrical energy"

The patent application has been filed.

About Us

HiTES Holding GmbH was founded with the aim of producing hydrogen and storing electricity, as well as developing, planning, constructing, selling and operating corresponding plants.

In February 2021, the three managing directors Dr. Dragan Stevanovic, Herbert Schmidt and Markus Rösch founded the company as a start-up. It currently employs eight people. HiTES Holding GmbH has applied for several patents for steam reforming using energy from biomass. A development cooperation with Fraunhofer UMSICHT already exists.

MARKUS RÖSCH

The architect and urban planner from Gebenbach has been active in the field of energy production since 2011. He is responsible for financing, personnel, funding and public relations.

HERBERT SCHMIDT

The energy and wood entrepreneur from Amberg has many years of experience in the energy, wood and biomass sectors. He is also involved in the construction of open-space PV systems. His responsibilities include the organization of raw materials, the supply of operating resources and the company's external contacts

DR. DRAGAN STEVANOVIC

The mechanical engineer for power plant technology and former scientist at the University of Belgrade has been working in Sulzbach-Rosenberg since 1991. The former head of department of the ATZ development center (legal predecessor of Fraunhofer Umsicht) takes care of all technical aspects at HiTES. The process on which our process for producing hydrogen from biomass is based was developed by Dr. Stevanovic and successfully tested for several years on a pilot plant. He has registered around 100 patents with the German Patent Office (DPMA), EU, USA, other European countries, and worldwide (WO).